STEL 3D Labs

3D printing with in-house machinery and industry-leading processes, delivered to your door in as little as 24 hours.

Since 2015, 3D printing and prototyping have been integral to everything we do at STEL. With over 50 years of combined experience, let us put your idea in the palm of your hand.

Our Process –

3D Printing | From Start to Finish

It starts with an idea.

Our Capabilities –

Prototyping Methodology

We’re an internationally approved supplier with in-house capabilities to create impactful designs on a limited budget. Together, we can execute your concept through world-class machinery, printing resources, and proprietary processes.

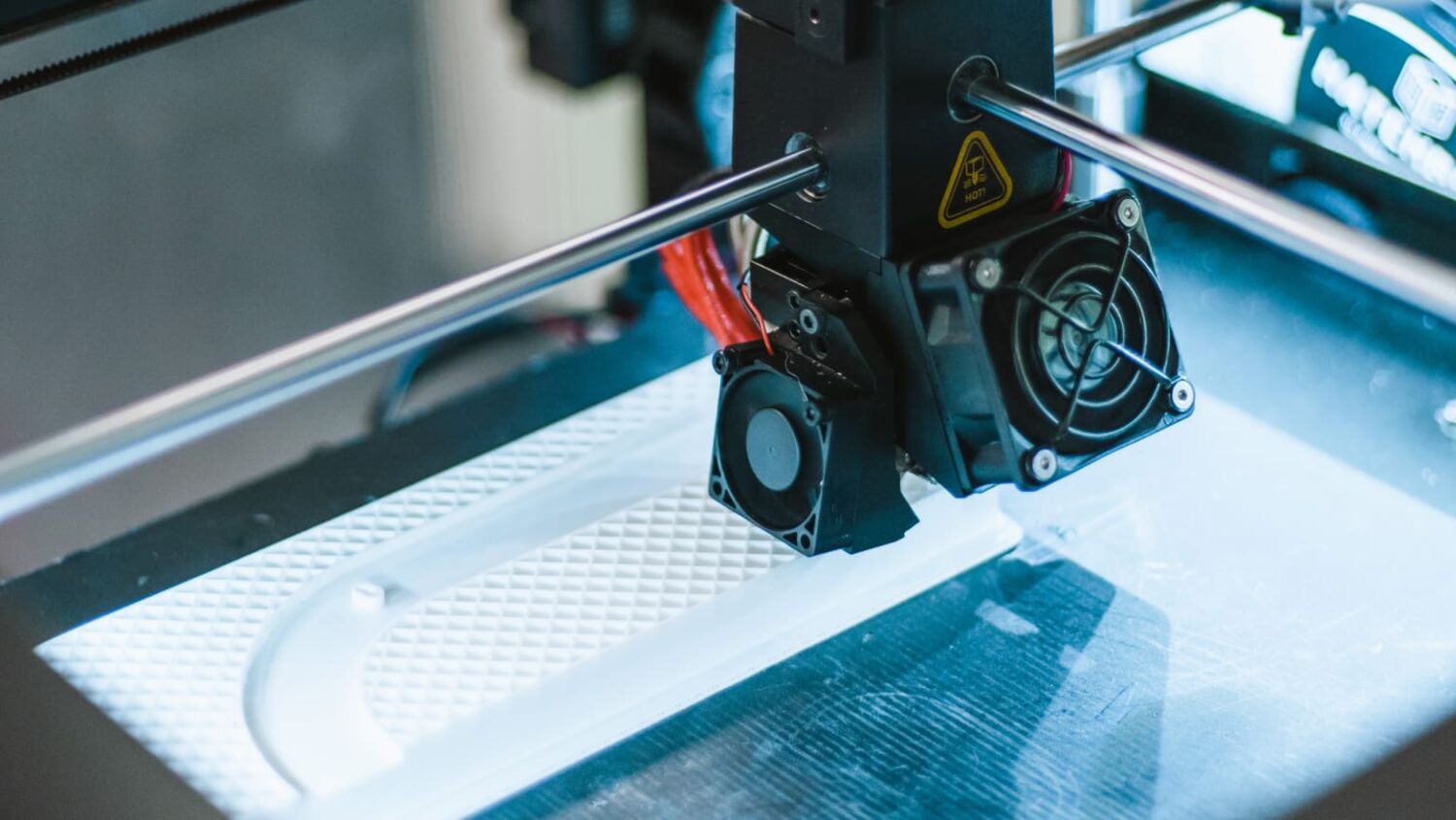

FDM

This printer is known as an FDM (Fused Deposition Modeling) printer. This is good for rough concept prototypes and form study models.

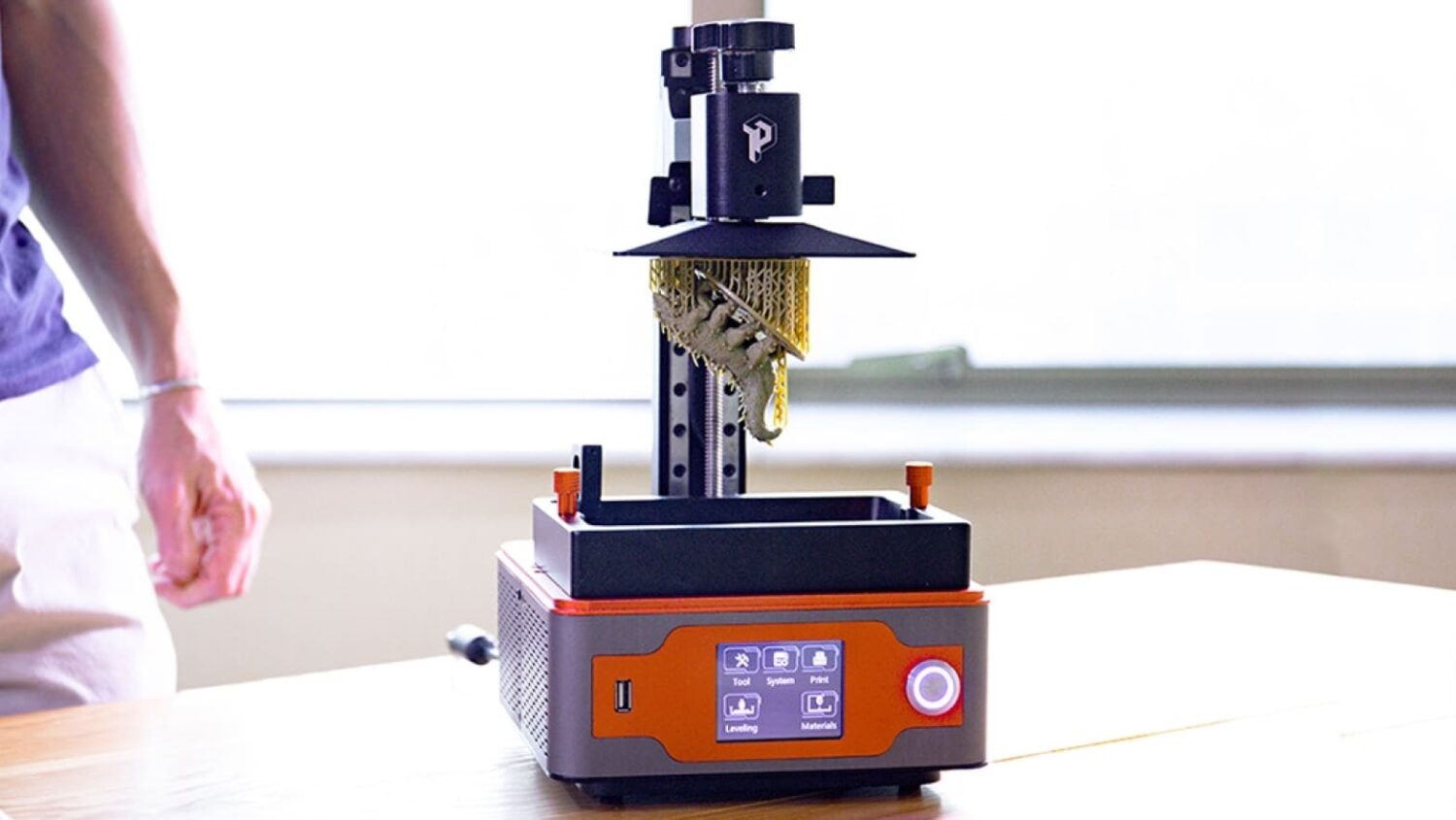

SLA

Ideal for high-resolution finishes on medium to large projects, SLA is a cost-effective way to get a durable, aesthetically pleasing prototype on a tight deadline. Outsourced SLA prints allow for more fine detail and a larger material selection.

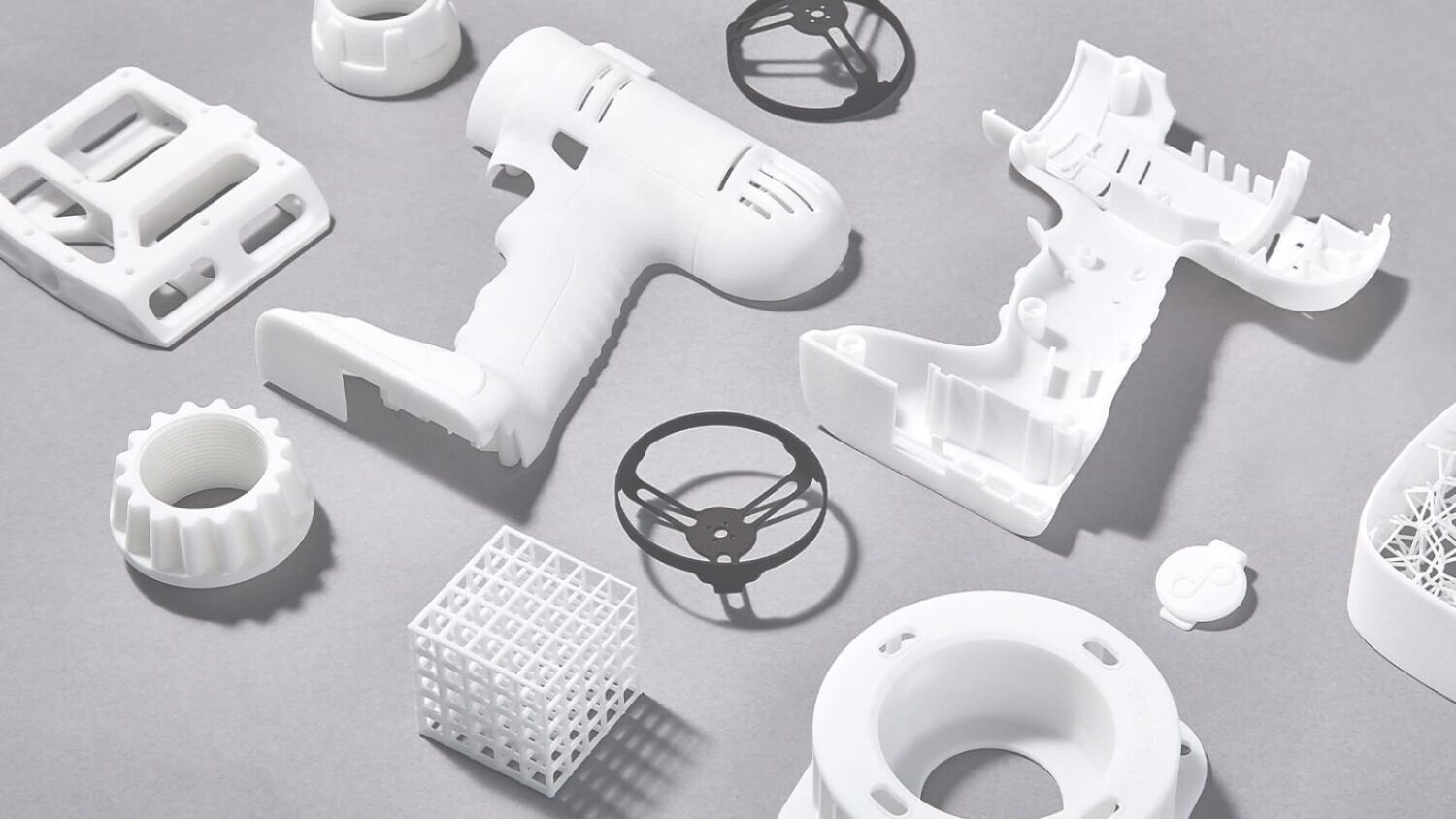

SLS

This powder-based additive is great for detailed projects that involve a high level of complexity, organic geometries, and parts that need to be durable.

MJF

MJF is quickly becoming the go-to choice for prototypes and production parts—enclosures, electronic housings, ducts, lattice structures, and parts that require great detail and durability.

VACUUM CASTING

This process uses a vacuum to fill a mold, giving the designer an air-free solution for details, undercuts, and wire/fiber reinforcement. Vacuum casting is the closest prototyping solution to a final injection molded production part, with the most accurate materials possible.

FINISHING SERVICES

To round out your prototype or production material, we can achieve high-quality finishes through painting, electrochemical processes, protective coatings, and more.

Our Capabilities –

Program & Skills

No tool or machine is as important as the mind behind it. As a product design firm, we rely heavily on rapid prototyping for development. We’re experts in 3D printing and consistently are at the cutting edge of its burgeoning technology. We’re highly trained in CAD software and a variety of 3D printing slicing software to achieve a high level of detail and precision for your project.

Ideation

We can help you hone your idea with the process in mind, giving input on the CAD model, printer, and materials based on your budget and goals.

Strategy

Through our experience in product design, we can help you make your print by strategizing the project based on your goals— prototyping, sizing, color, durability, etc.

Execution

Once the idea and printing strategy is set, we can use our 50+ years of combined experience to refine CAD models for optimal printing and execute detailed perfection.

Like what you see?

Our Team –

Meet The Engineers

We’re not just a 3D printing team. We’re a team of creatives and big thinkers, who use 3D printing as a tool to execute impactful concepts. With experience across mechanical engineering, industrial design, product strategy, manufacturing, and more—we have a passion for creating and bringing big things to life.

Your Capabilities –

Types of Projects

STEL 3D Labs sits in the heart of our Santa Barbara product design studio. We’re using our printing capabilities day in and day out for rapid prototyping, user testing, and quality assurance. Whether you need a simple, well executed 3D print or a highly detailed product prototype, we’re equipped and experienced in both.

Individual

3D Printing

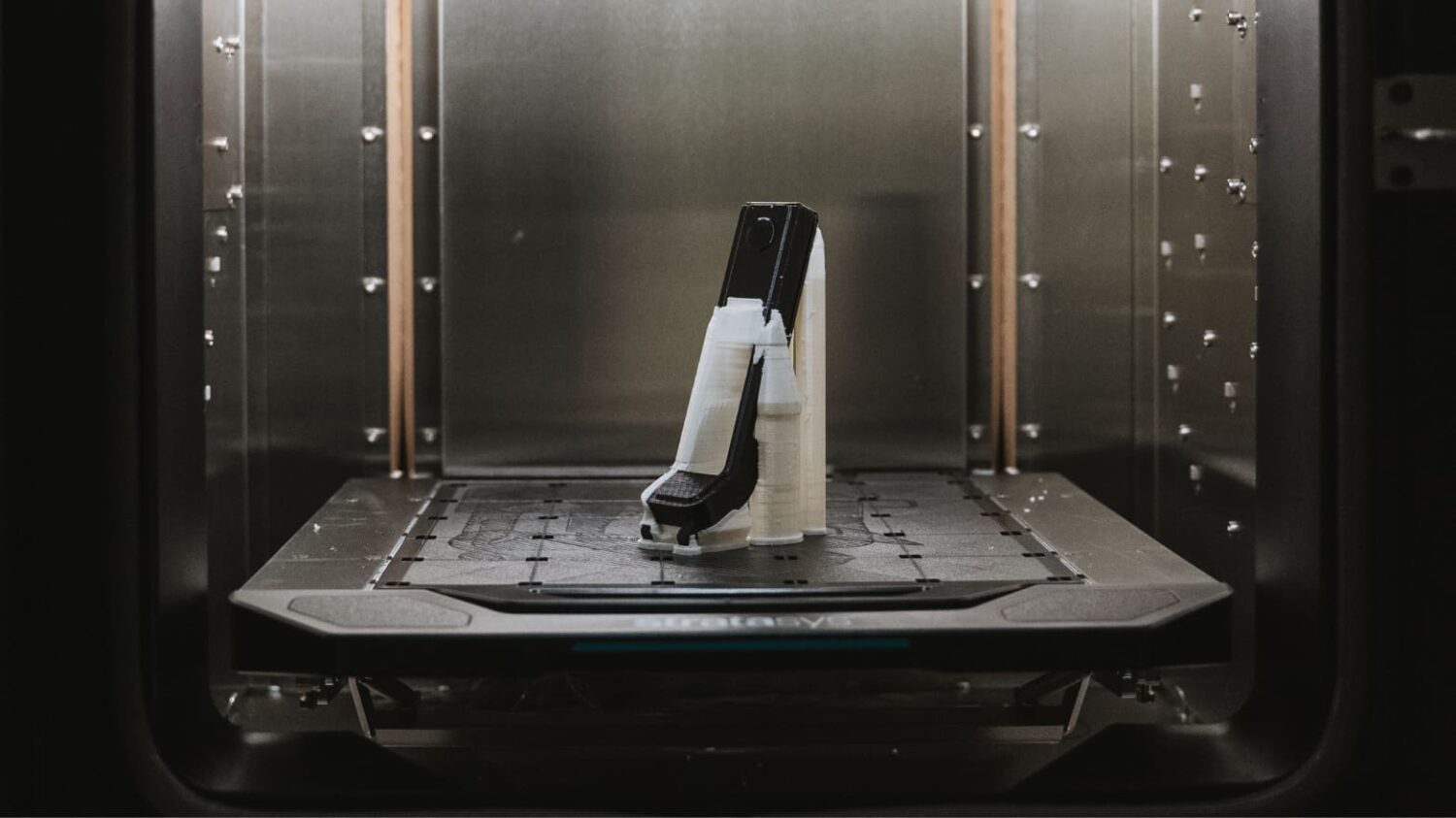

Whether you need knowledge and instruction, or simply access to machinery, we have full capabilities to make your CAD file a reality, develop prototypes, or to fill small production gaps.

Product Design

3D printing has revolutionized prototyping for product development. We collaborate with clients to create rapid iterations for user testing, sizing, and general concept validation.

2M

Parts Produced

300+

Products prototyped

20+

Manufacturing partners

With our product designers, we’re in the business of bringing your idea to life. All it takes is your idea.

Let’s get started