Meet Santa Barbara’s Premiere 3D Printing and Prototyping Resource

At STEL, we’re dedicated to innovation and accessibility above all else. Regardless of the project or client, we foster a creative environment where innovators solve real-world problems with practical solutions. It’s for this reason that we’ve launched STEL 3D Labs, Santa Barbara’s premiere 3D printing and prototyping hub. With our influential position in the Central Coast product development community, we provide access to cutting edge technology that yields innovative and impactful prototypes, enabling efficient delivery of products to market.

The 3D Lab was built to bring product visions to life. It’s why we started 3D printing in the first place, and why it remains an integral part of our studio today. With new technology and expert engineers, we’re streamlining the path to production and reducing expensive iteration cycles.

We Go Way Back

3D Printing within our studio dates back to STEL’s origin. Co-Founders Ryan Olson and Pete Ducato started STEL in their garage with nothing but a 3D printer and a handful of website domains. It was the beginning of our business model, to bring accessible 3D printing to Santa Barbara. We’ve come a long way since then, with our expertise evolving into full turn-key product development, leveraging 3D printing and prototyping from beginning to end.

“3D printing is integral to product design and development. It has really fostered the ability for the team to create award winning designs. Without 3D printing, and our ability to quickly iterate and learn, our designs would not be as advanced nor as quick to the market as they are.”

-Ryan Olson, STEL Co-Founder and COO

The tech-driven roots of Santa Barbara allow local product developers to quickly iterate ideas, with in-hand prototypes delivered in a matter of days. STEL’s additive manufacturing expertise and know-how can help guide process and material selection and even prototyping strategy based on program goals. We are here every step of the way.

Our lab has evolved from hobbyist level printers, to the professional setting it is today. As we continue to grow, our capabilities and service offerings will provide an even more impactful benefit to our customers.

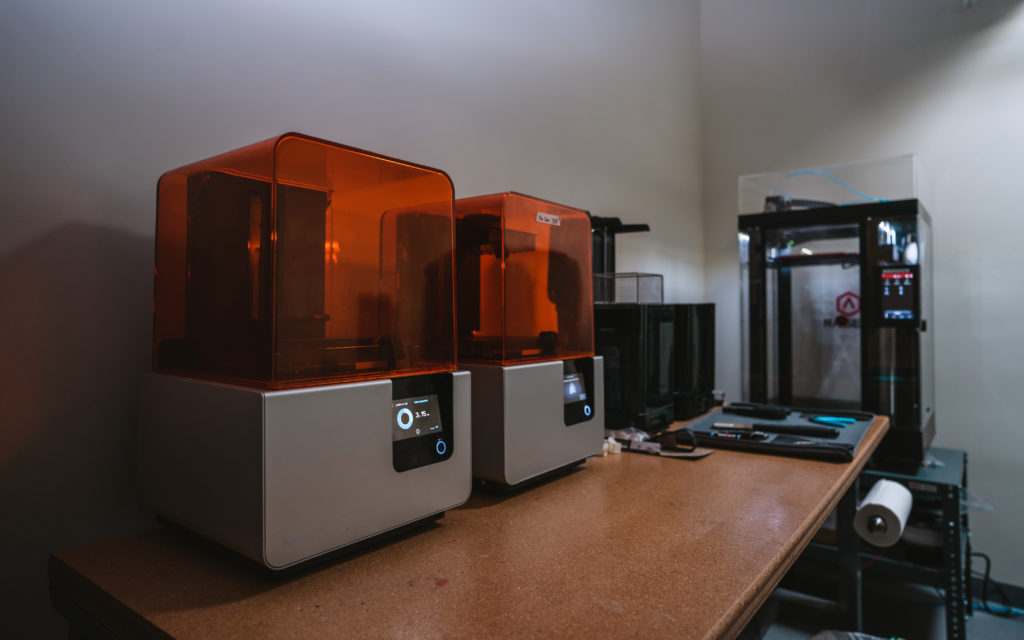

“When we first started, we had printers crammed into a multi-use space that would tend to get dirty, subjecting materials to contamination. All of the post-print processes were analog and very labor intensive. Today, we have a dedicated 3D printing area in a clean, vibration-isolated and temperature-controlled environment. In this room, there are designated cleanup stations and machines to cure prints and dissolve supports, reducing hands-on time and producing more consistent, repeatable results.”

Jared Naito, STEL Director of Engineering

The lab is built on efficiency. Touting various additive manufacturing technologies, with dedicated prep and post processing stations, STEL 3D labs is the synergy of additive manufacturing with expert designers and engineers.

Inside the Lab

In house, we have 4 dedicated 3D printers, each with their own capabilities for specific project demands. The four printers include two Formlabs stereolithography (SLA) machines, a Stratasys fused deposition modeling (FDM) machine, and a Raise3D Pro2 Plus (FDM) machine.

The high-layer resolution achievable on the Formlabs SLA printers assists engineers in evaluating form, fit, and the more intricate details of design. These printers are perfect for the most complex parts with intricate geometries ranging from concept models to functional models.

The Raise3D Pro2 Plus, one of our FDM printers, is a great value-option for faster turnarounds and quickly evaluating the forms and proportions.

Lastly, the Stratasys F170 is our most powerful in-house machine, able to use engineering-grade materials and dissolvable supports for dynamic modeling and design flexibility.

3D printing is a critical tool in the STEL studio to put a product concept in the palm of your hand. In product development, speed and accuracy are key, and our process with 3D printing allows us to bring precisely designed products to market quickly.

“3D Printing will give you a quicker and more accurate answer in the long run when it comes to product design. While we are able to create designs using simulations and equations, it’s a much easier process with 3D printing. You usually want to validate your designs and calculations when creating a product, and the 3D printer accurately validates that.”

Mulin Yang, STEL Mechanical Engineer

Our aim is to help local companies and entrepreneurs innovate products to their full potential by utilizing our in-house printers and expert team of engineers and designers. With our team, concepts are efficiently refined, and ultimately commercialized into real-life solutions. Having a tangible prototype allows for a smooth development process, and we strive to put that prototype into the hands of our clients to enable groundbreaking product creation.

The Power of a Prototype

3D printing is a foundational element of the STEL studio, but by no means the only element. We built our 3D Lab to make the most of our entire product design process, helping to cultivate an ecosystem for creatives in our community and beyond. We’re experts in 3D printing, prototyping, product concepting, and so much more; we are big thinkers; and this perspective percolates throughout our client relationships.

3D printing is a great way for us to begin long-lasting relationships with trusted collaborators. Some of our closest partners have come through the prototyping process, looking to bring their biggest ideas to life.

“We would not have the same client depth without 3D printing. We’ve had several clients originate from the 3D printing service, it’s been a fantastic introductory tool. ”

Jared Naito, STEL Director of Engineering

3D printing is the catalyst for a collaborative partnership. Our engineers can help create an effective prototype, as well as a prototype that’s reproducible in the manufacturing pipeline after it leaves our Lab. We want our clients to come away with something that’s not only innovative, but effective, realistic, and allows them to start bringing their product to life.

“Having access to a 3D printer in the office allows for more ‘out of the box’ manufacturing when it comes to designing the product because of minimal building restraints. You are able to create more layers within a 3D printing product, allowing for more creative solutions.”

Everett Johnson, STEL Mechanical Engineer

We’re a local printer first and foremost, and we’ve found that the most creative ideas come from those moments at the drawing board, together. We’re ready to grow the Santa Barbara product development community, beginning with your idea. Check out STEL 3D Labs to get started.

STEL has evolved greatly over the past five years. The team has grown, our skill set has widened, we’ve moved into a bigger office, and we’ve adopted new technology to expand our capabilities. Throughout all of this growth and development, one thing has remained the same—STEL’s commitment to its guiding pillars of deliberate design, sustainable engineering, and meaningful relationships. It’s these pillars that lay the foundation of every project we take on, and at the core of how and why we do what we do.

01

Quality Over Quantity

Prioritization of depth over breadth has always been a guiding principle for STEL’s

practice. When we take on a project, we don’t just see the product at the end of the

development process, we see every step leading up to it, every person involved, every

opportunity that could come about from it.

Above all, we pursue projects with purpose.

Our team focuses our talents on completing perfectly-executed, innovative designs

rather than spreading its strengths to churn out conventional products that saturate the market. When STEL sets out to create, we do so with the intent to bring a one-of-a-kind design to life. Our industrial designers and engineers are constantly collaborating to push the boundaries of function without compromising form to create products that will make an impact.

02

Partnership Beyond the Project

At STEL, we look at more than a proposal when selecting our portfolio of projects; we

look to the future of a partnership. Our directors carefully examine a company’s core

principles, start-up mentality, commitment to a mission, and enthusiasm for sustainable design when evaluating potential partners. We take our time to carefully curate internal and external connections with clients to ensure commitment and professional fit that can extend beyond a first project. These well-developed, purposeful relationships enable both STEL and our partners to call on each other for future projects and endeavors.

Many of these partnerships have grown into friendships outside the office as well; it is

not uncommon to see team members of STEL and collaborating companies bombing

down a bike trail or tackling local climbing routes in a race against sunset after work.

03

Behind Every Great Product is a Great Story

A successful product is more than just a well-executed design, it’s a labor of love.

Behind every idea that STEL brings to life is a story, written by a passionate team,

which we use to craft a product’s brand. It’s that team’s passion that drives a product’s

story forward, and is at the base of our partner’s brands, which gives them a competitive edge as they take on larger companies.

Our team carefully constructs marketing plans tailored for a well-researched target audience, to amplify a brand’s voice to be heard over the hum of a saturated market. We strive to lay the foundation for our partners and their brands so they may grow around the products they have designed. STEL’s understanding of every facet of the production process, from renders to marketing, enable us to provide end-to-end services for a successful product development through to its launch.

04

Real Recognizes Real

It is no coincidence that STEL’s clientele consists of passionate, purposeful partners.

Like attracts like in this regard as our team’s industrial designers and engineers bring

their own passion for invention into the office every day. We make sure our clients are

always involved with every step of the product development process to maintain a

constant state of collaborative creativity and to ultimately ensure expectations are

exceeded.

The STEL team is driven by a genuine love for creation, not just the bottom line, as we

seek to create products for companies with a purpose. It is our commitment to the core principles of ethical engineering and honest design that companies are proud to be a part of.

05

Looking at the Big Picture

STEL’s dedication to sustainability extends beyond our partnership with 1% For The

Planet and our incessant pursuit of adventure after work. With every product born in

our studio, we design with the absolute end in mind; each step of our design process is conservation-focused to culminate in incredibly sustainable final products. Our library of recyclable, plant-based, and non-toxic materials allows us to create products with minimal environmental impact well beyond their lifetime. To improve the sustainability of production both in our own studio and with our clients, we utilize materials, manufacturers, and design methods that are environmentally conscious. In doing so, STEL has procured a toolbox of sustainable resources that is readily available for use by our in-house designers.

An ongoing dedication to ethical production and commitment to sustainable design have played a crucial role in our success as a firm, and truly reflect our passion as people. We are pulling inspiration for our product design from the world around us everyday, so we have to keep protecting that world top of mind always. These guiding pillars have served us well as our final products reflect the integrity and innovation of the STEL team.

01

Where We Started

Over the last five transformative years, STEL has grown from humble beginnings into a Santa Barbara hub for innovative design. What started as an idea between creatives in an IHOP booth quickly took life in June of 2015. We opened our first design studio connected to a manufacturing shop with just enough space to bring our first projects to life.

Our initial team of 5 creatives started designing and prototyping products for some of our first partners, who we still are partnered and consistently working with today. Our portfolio started to expand, and as we started to take on more and more clients with an exciting and diverse array of products that needed developing, we began to grow our team to meet those needs.

02

Our Growing Team

What began as a dream of two passionate engineers has grown into a team of 20+ creatives since 2015. Our team of highly skilled industrial designers, engineers, graphic designers, copy writers, and project managers have had the opportunity to collaborate with local and global clients, ranging from startups to Fortune 500 companies, to successfully deliver over 300 products to market.

With every addition to the STEL family, our collaborative design process becomes more precise, creative, and innovative, ultimately allowing us to develop top of the line products for our clients. And the best part? Our team will only continue to get better as we work together on more difficult projects, refine our skill sets, and solve whatever problem is put in front of us.

03

Scaling Up and Moving Out

As our team and set of skills expanded, we quickly outgrew our last office both in size and in ability to execute cutting edge products. Today, we’re proud to have moved to a beautiful new office space to accommodate everything we’ve grown.

Iterative product design is more efficient and creative than ever with our 3D printing lab, engineering workshop, ample prototyping space, and plotter printing capabilities, as well as a showcase to display some of our favorite prototypes to date. For accommodating our supply chain as well as our in house startup, a full portion of the office is dedicated to mail fulfillment to increase efficiency. To support our company growth, creative collaboration, and team well being, we’ve expanded into a private conference room, several meeting spaces, a breakroom, and an open office layout in the center of it all. To see what our office was in 2015, to where it is now, and looking to what it can be in the future, our growth as a firm has manifested physically in the space we work in as we continue to build an environment where design can thrive.

04

Our Extended Family

Our success as a growing business did not happen overnight, nor did we do it alone. With only 44% of businesses successfully passing the 5 year mark, we owe a huge thank you to our partners for helping us in our growth and success as a design firm since 2015. The teams we’ve been fortunate to partner with, both down the street in Santa Barbara, or across the world, have been an integral part to not only our growth as a firm but our growth as designers and innovators.

Our firm is upheld by pillars of design and grounded in collaboration with others, recognizing the invaluable asset of teamwork. Because we strive to partner with businesses that share our same values of bringing mission-driven designs to market by merging form with function, nearly 90% of our client base return to work with STEL on additional projects. Not only do our partnerships frequently extend beyond a single project, our clients continue to recommend our services to their professional networks and friends as well. The partnerships we have developed are more than just business relationships, they have become a crucial building block in the foundation of our firm.

We Couldn’t Have Done it Without You

Thank you for our first five years, and here’s to our next five and beyond. We truly could not be the firm we are today without your support, and can’t wait to see what the future of design at STEL holds.