Our mission to give back.

Combating the spread of COVID-19 is no easy task. STEL continues to aid efforts in curtailing the spread of this novel coronavirus on multiple fronts. In-house prototyping machines and 3D printers have been running full clip to simultaneously produce immediate protection for the medical community and expedite the development process for consumer protection solutions. Whether through our own initiatives or with long-term partners like Nomad and KeySmart, the STEL team has been working hard to aid in the fight against this unprecedented pandemic.

01

Prototyping on-site for faster production.

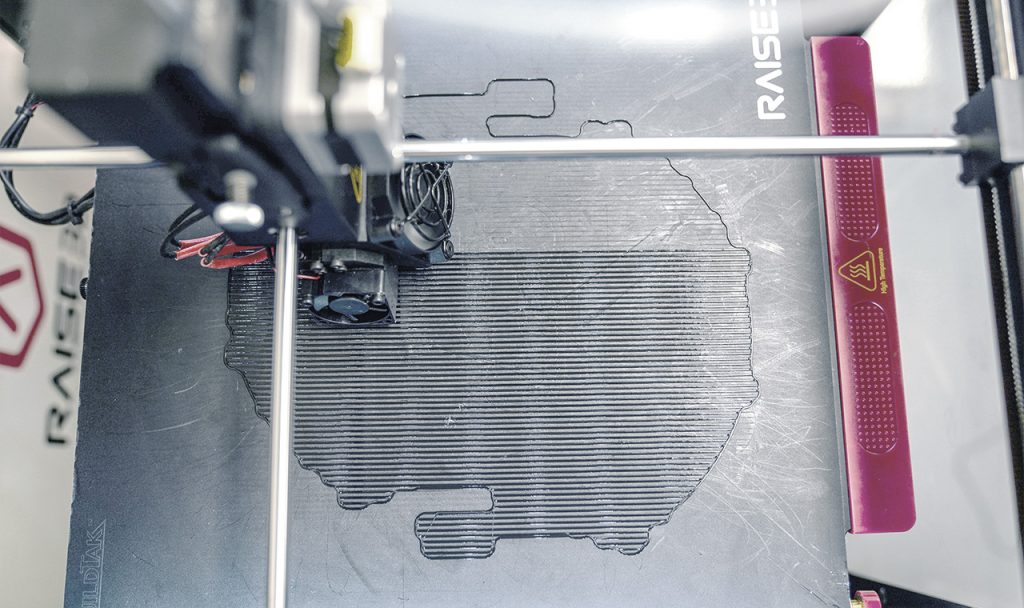

On-site prototyping and 3D printing capabilities have proven invaluable for STEL’s creation process. These in-house resources reduce the turn-around and delays associated with outsourcing and allow us to test multiple design iterations per week. This gives our designers and engineers the ability to explore more directions in greater depth, resulting in more thorough, robust designs in an expedited timeframe—especially valuable aspects when designing products to combat the time-sensitive coronavirus crisis.

02

Swiftly delivering solutions for market adoption.

The pace at which market landscapes are evolving has never been greater. Fortunately, STEL is uniquely equipped to handle these constantly changing environments. Our agility and quick-turn design capabilities have been crucial in realizing many COVID-19 response projects.

Mike Tunney, CEO of KeySmart, explains, “STEL’s fully integrated design capabilities have allowed us to quickly develop solutions [for] a changing market.” Whether it’s an everyday face mask, CleanGrab device, or other product currently in development, STEL swiftly delivers high-value designs to customers who need to get to market fast.

03

Designing masks for everyday use.

Following the CDC’s call for face masks to be worn in public, STEL partnered with long-time client KeySmart to develop a well-designed face mask for general use. Given the public’s reluctance to wear face coverings on the grounds of discomfort and unattractive appearance, the ultimate goal of this project was to encourage face mask adoption and reduce infection transmission by creating a comfortable, stylish product that people actually want to wear.

STEL leveraged our extensive soft goods supply chain to sample and select the necessary materials to complete this PPE tailored for everyday use. Our robust supplier network has been instrumental in providing a streamlined, quick-turn solution for this essential product.

04

Utilizing 3D printers to shield the community.

STEL understands the value of a rapid response during a crisis like the COVID-19 pandemic. Our team has been working tirelessly to quickly and efficiently produce Personal Protective Equipment (PPE) that protect the general public and ease the shortages our medical community is experiencing. Our adaptability and committed spirit of innovation have been instrumental in the successful completion and introduction of designs and products in a matter of weeks.

Always keeping those on the front lines of this crisis forefront in our minds, STEL continues to leverage its in-house capabilities to augment supplies for the severely strained medical supply chain. Using our on-site prototyping and 3D printing assets, we have been producing, assembling, and donating face shields to medical facilities right here in Santa Barbara.

05

Procuring masks for donation to local hospitals.

Looking beyond our office walls, we knew there was still more we could do to contribute. Utilizing our extensive supply chain and well-established manufacturing relationships, we continue to actively source PPE to ease the strain on the medical supply chain. We’ve donated thousands of surgical masks, sanitations wipes, and face shields to date to give heroic medical personnel the protection they need.

06

Business as usual.

Despite the many changes this crisis has brought to the workplace, the STEL team continues to be as creative and productive as ever. Working from the safety of their own homes, our engineers and designers are focusing on innovating next-generation products. Our team is using various telecommunication tools to maintain the proven collaboration and communication processes that enable us to deliver products of the utmost quality, on-time and on-budget.

STEL "Surf's Up" Team MeetingAlthough timelines are uncertain, STEL understands that these unprecedented times are temporary. No matter how long it takes to put this pandemic behind us, STEL is eager and committed to helping the community in any way we can. We encourage you to reach out to discuss any project ideas you may have and look forward to collaborating.

The Power of Turnkey Product Design

Truly exceptional products are found at the intersection of design and engineering. The unique collaborative process between designers and engineers at STEL has proven to be the key to countless successful designs for a wide range of clients, that not all design consultancies can boast. Each team is crucial to the design process and the realization of a product as they work hand-in-hand to provide synergistic effects unseen at most agencies.

01

The Best of Both Worlds

Having designers and engineers work closely together under the same roof is an invaluable asset to STEL’s end-to-end services. Most design firms specialize exclusively in one discipline—industrial design or engineering. This sole focus necessitates the critical involvement of multiple outside agencies, resulting in design direction conflicts, responsibility gaps, and severe delays to development timelines. This ultimately translates to a loss in efficiency, a reduction in budget efficacy, and a compromised design process.

By having both designers and engineers collaborating in-house, STEL can push the boundaries of design without losing sight of product quality and manufacturing. In this way, STEL fosters greater creative dialogue and captures efficiency gains associated with real-time cooperation managed under the same directional umbrella.

02 | Fluidity of Collaboration

STEL buzzes with a constant hum of collaboration as our team members consult one another for insights and recommendations based on areas of individual expertise. The swivel of a desk chair is all it takes to huddle with a seasoned engineer or pick the brain of an expert designer.

Having both teams commingle within the same workspace allows for a more fluid, open dialogue. Designers can push the envelope without pressing too far, as engineers provide input every step of the way. Engineers can modify designs to improve reliability and ready for manufacture without compromising forms and aesthetics, as designers provide guidance around every challenge.

Every product STEL creates has limitations and restrictions that designers and engineers must consider and navigate around. This requires what sometimes feels like endless iteration between design and engineering, but the process is paramount to attain the absolute best designed and engineered solution. Because interactions between designers and engineers happen organically, as needed, and in real-time, development occurs at a faster pace with fewer expended resources. This streamlined process gives clients better bang for their buck, designing better products within a minimized time frame.

03 | Teamwork Makes the Dream Work

Close cooperation between both teams is essential in overcoming design obstacles. Engineers define interface requirements, keep-out zones, and internal space allocations before designers even begin to sketch concepts. Designers keep construction and manufacturing constraints in mind while they perform their concepting work, working with engineers to ensure their designs are feasible from production and cost perspectives. Engineers translate designs into final models and drawings that are ready to manufacture, consulting designers whenever aesthetic changes must be made. Along the way, discussions are had and ideas are bounced between both teams to ensure the common goal of an optimal product is achieved.

Our Philosophy In Practice: Meet Gnarbox

Gnarbox 2.0 houses a powerful internal computer system within a fully enclosed and ingress protected casing. STEL’s engineering team was tasked with finding a solution to prevent the system from overheating under a very strict set of size, power, safety, and environmental exposure constraints. With active cooling and open venting out of the question, STEL’s lead creative director (Marco Vanella) consulted STEL’s team of designers and engineers to find a suitable solution.

Through multidisciplinary brainstorming and collaboration, the team came up with the innovative solution to incorporate an overmolded, finned heat sink into the rugged aesthetic of Gnarbox 2.0. This functional modification was massaged by the team to simultaneously satisfy engineering constraints and add a “signature” design feature.

Getting a product from sketchboard to market is nothing short of a Grand Slam tennis match between STEL’s industrial design and engineering teams. This continual give-and-take process is a crucial pillar of product development, as it allows STEL to efficiently pioneer new designs while holding focus on the realities of reliability and production.